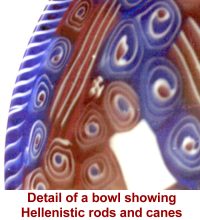

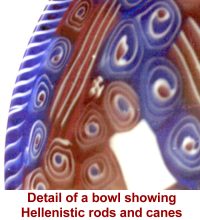

This Newsletter covers the Hellenistic forms of rods and canes (for definitions, see Newsletter 4). This group can be divided into rectangular and circular cross-sectioned types.

Common colours for network canes are white or yellow spirals in a colourless matrix, with white spirals in a blue or purple matrix also being popular. Other colours are known, including golden brown and dark green as matrix colours and opaque red and green as spiral colours.

Common colours for network canes are white or yellow spirals in a colourless matrix, with white spirals in a blue or purple matrix also being popular. Other colours are known, including golden brown and dark green as matrix colours and opaque red and green as spiral colours.

The Making Process:

All of the processes described below can be performed by one person working alone.

- Rectangular rods of a single colour are made by shaping and cooling a gather of glass on a marver, carefully re-heating and stretching it using a pair of pincers.

- Rectangular rods with a single central strip of a contrasting colour running from top to bottom of the cross-section can be made as one 'hot' operation and do not have to be assembled and re-heated.

A gather of glass is shaped into a rectangle and cooled, and is then bent to resemble the head of a golf club. The extent of bending depends upon the 'angle of attack' necessary when gathering the second colour from the furnace, but the base of the 'club head' should be angled so as to match the horizontal surface of the glass in the pot when gathering (1). The 'club head' is touched on the surface (2), pulled up and scraped on the edge of the pot (3). The excess glass is scraped off, and the trail can be cast off by melting it against the just-gathered molten glass (4).

|

|

This produces a rectangular cross-section with a thin strip of coloured glass along one side, all of which can be re-heated and centred on the bit iron (5). |

To create a strip with a central stripe, the glass can be stretched and folded back on itself, but a method which is less wasteful of glass is to break the strip across its mid point, turn the broken section around and attach it to the part still connected to the iron (left). (For an even thinner stripe, only half of the length of the 'club head' need be gathered onto.)

To create a strip with a central stripe, the glass can be stretched and folded back on itself, but a method which is less wasteful of glass is to break the strip across its mid point, turn the broken section around and attach it to the part still connected to the iron (left). (For an even thinner stripe, only half of the length of the 'club head' need be gathered onto.)

To form the rod, the glass has to be re-heated and shaped to a rectangle, further re-heated, gripped with a pair of pincers and stretched.

- An extension of this method can be used to trap two or three stripes of glass in the rod, and even to use more than one main colour.

-

Similarly, this method can be used for trapping a thin strip of glass running from side to side in a rectangular bi-colour rod, or for backing one colour with another. In this case, when gathering, the strip of glass is not vertical (as for the 'club head'), but horizontal, forming a tongue-shape (right).

Similarly, this method can be used for trapping a thin strip of glass running from side to side in a rectangular bi-colour rod, or for backing one colour with another. In this case, when gathering, the strip of glass is not vertical (as for the 'club head'), but horizontal, forming a tongue-shape (right).

-

Circular canes with a star pattern have to be built from sections of rectangular bi-colour rods to form the rays and a single colour or bi-colour circular rod to form the centre.

Circular canes with a star pattern have to be built from sections of rectangular bi-colour rods to form the rays and a single colour or bi-colour circular rod to form the centre.

Our method is to cut the rectangular rods into 25mm lengths, stack them on their sides against each other (left), re-heat in order to fuse them and bend the fused unit into a C-shape. This is then stood upright and the central rod is inserted (right). The assemblage is picked up on a bit iron, re-heated, marvered to complete the joining and fusing of the components, re-heated again and stretched to form the cane.

Our method is to cut the rectangular rods into 25mm lengths, stack them on their sides against each other (left), re-heat in order to fuse them and bend the fused unit into a C-shape. This is then stood upright and the central rod is inserted (right). The assemblage is picked up on a bit iron, re-heated, marvered to complete the joining and fusing of the components, re-heated again and stretched to form the cane.

- Circular canes with a spiral pattern are of two types: those with a central rod and those without. The first part of the process is to make a 150-230mm length of glass with a rectangular cross-section, the matrix being backed by the colour which becomes the spiral (usually white or yellow).

- For a spiral with a central rod a pre-heated short length of circular-sectioned rod (c.25mm) is picked up on the tip of the strip of glass. In order to ensure that the central rod is outlined by the spiral colour, that particular colour must adhere to the central rod (below left). It is then re-heated and rolled up using a marver, and, if necessary, a pair of pincers or a battledore (below right).

When fully rolled the spiral is cracked off the bit iron and stood upright on the marver, the bit iron is re-heated, and its softened glass flattened and used as a pontil to pick up the spiral (left). It is once more re-heated and stretched as normal. It can take one person 12-15 minutes to make a spiral cane, which can be up to a metre long.

When fully rolled the spiral is cracked off the bit iron and stood upright on the marver, the bit iron is re-heated, and its softened glass flattened and used as a pontil to pick up the spiral (left). It is once more re-heated and stretched as normal. It can take one person 12-15 minutes to make a spiral cane, which can be up to a metre long.

- For a spiral with no central rod the process is similar. If the length of glass is rolled up with the spiral colour on the outside so it does not meet itself in the middle, a thin layer of glass of the matrix colour must be gathered over the spiral to prevent the spiral colour appearing on the outside.

- Network canes There are several ways of preparing the proto-cane. A small gather of the matrix glass is marvered to a cylindrical shape and:

- a short rod of glass for the spiral is picked up on it;

- a gather of glass for the spiral is trailed along it;

- or the matrix is marvered to a wedge or 'golf club shape' (see above) and dipped into the pot containing the glass for the spiral in the same way as for the rectangular rods.

It is reheated and marvered flush, then fully reheated until the glass flows. It is allowed to slowly lengthen and gradually cool a little, and the end is grasped with a pair of pincers. It is carefully stretched whilst rapidly turning the gathering iron to impart the spiral. This can be done by rolling it along the chair arms, repeatedly returning it to the start position, or by rotating it in a 'V'-shaped slot in the chair arm. In this way a 60cm length can be made.

- It is worth noting here that more than one rod, trail or gather can be added onto the same matrix in order to form spirals of more than one colour or to give the impression of tighter spiral-winding. Examples of both are found on original Hellenistic and Roman vessels.

- There is evidence that the cane lengths in some early spiral-pattern network cane bowls are as much as 2m in length (pers. comm. Bill Gudenrath). These would have to be made by two people working together: drawing a cane out by simultaneously walking away from each other whilst rotating the gathering irons along their long axis. A problem here is that the ensuing spiral pattern may not be tight enough. One solution would be to attach more than one trail for the spiral.

All of the rods and canes need annealing - including single colour rectangular rods which are too thick and wide to be snapped easily with no annealing. The one exception is the spiral cane, which can be used un-annealed.

The canes are then cut into florets as described in Newsletter 4, or, in the case of rectangular cross-sectioned rods, snapped into portions.

Reasons to trap glass longitudinally:

There are several reasons why this is done:

- To enhance or change the perceived colour. A thin layer of white either backing or trapped within dark cobalt blue will brighten the colour. Yellow within dark copper blue-green will give a brighter yellow-green.

- To make a small amount of coloured glass go farther. Yellow and (later, in parallel strip canes) bright red were probably expensive glasses as they were time-consuming to make (involving at least two stages - see Newsletter 3). Opaque white, although an easy colour to make now, may have been less so in the past. Trapping these colours between layers of colourless glass would have been more economical.

- To alleviate compatibility problems. For two or more glasses to be successfully fused in a pattern, their coefficients of expansion must be within fairly tight limits. If they are not, one glass contracting at a faster rate than another glass upon cooling will cause stress in both glasses which can lead to cracking. Both yellow and red can contain a high amount of lead oxide, which will substantially lower the coefficient of expansion from that of the normal soda-lime colourless and translucent coloured glasses. If they are used sparingly and encased within colourless glass, the stress is, in effect, locked in with them. We do this successfully in the case of yellow glass, which can crack if used as a thin backing layer, but which is stable when encased in colourless glass.

Mark Taylor and David Hill

|

vitrearii @ romanglassmakers . co . uk |

0044 (0)1264 889688 |

Unit 11, Project Workshops, Lains Farm, Quarley, Andover, Hampshire SP11 8PX, UK

Our website is revised regularly:

www.romanglassmakers.co.uk

We are hoping to present our work on ribbed bowls as a poster/display at the AIHV Congress in London in September 2003.

To create a strip with a central stripe, the glass can be stretched and folded back on itself, but a method which is less wasteful of glass is to break the strip across its mid point, turn the broken section around and attach it to the part still connected to the iron (left). (For an even thinner stripe, only half of the length of the 'club head' need be gathered onto.)

To create a strip with a central stripe, the glass can be stretched and folded back on itself, but a method which is less wasteful of glass is to break the strip across its mid point, turn the broken section around and attach it to the part still connected to the iron (left). (For an even thinner stripe, only half of the length of the 'club head' need be gathered onto.)

Similarly, this method can be used for trapping a thin strip of glass running from side to side in a rectangular bi-colour rod, or for backing one colour with another. In this case, when gathering, the strip of glass is not vertical (as for the 'club head'), but horizontal, forming a tongue-shape (right).

Similarly, this method can be used for trapping a thin strip of glass running from side to side in a rectangular bi-colour rod, or for backing one colour with another. In this case, when gathering, the strip of glass is not vertical (as for the 'club head'), but horizontal, forming a tongue-shape (right). Circular canes with a star pattern have to be built from sections of rectangular bi-colour rods to form the rays and a single colour or bi-colour circular rod to form the centre.

Circular canes with a star pattern have to be built from sections of rectangular bi-colour rods to form the rays and a single colour or bi-colour circular rod to form the centre.

Our method is to cut the rectangular rods into 25mm lengths, stack them on their sides against each other (left), re-heat in order to fuse them and bend the fused unit into a C-shape. This is then stood upright and the central rod is inserted (right). The assemblage is picked up on a bit iron, re-heated, marvered to complete the joining and fusing of the components, re-heated again and stretched to form the cane.

Our method is to cut the rectangular rods into 25mm lengths, stack them on their sides against each other (left), re-heat in order to fuse them and bend the fused unit into a C-shape. This is then stood upright and the central rod is inserted (right). The assemblage is picked up on a bit iron, re-heated, marvered to complete the joining and fusing of the components, re-heated again and stretched to form the cane.

When fully rolled the spiral is cracked off the bit iron and stood upright on the marver, the bit iron is re-heated, and its softened glass flattened and used as a pontil to pick up the spiral (left). It is once more re-heated and stretched as normal. It can take one person 12-15 minutes to make a spiral cane, which can be up to a metre long.

When fully rolled the spiral is cracked off the bit iron and stood upright on the marver, the bit iron is re-heated, and its softened glass flattened and used as a pontil to pick up the spiral (left). It is once more re-heated and stretched as normal. It can take one person 12-15 minutes to make a spiral cane, which can be up to a metre long.