Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

|

|

2020 Furnace and Lehr at Quarley - Firing Four - Furnace Performance

Projects: 2019 Onwards

Shelter Build

Wood Gathering and Processing

General Preparation

Firepit Construction

Furnace Installation

Lehr Installation

Floodproofing

Firings One and Two

Firing Three

Firing Four

Firing Five

Firing Six

------------------------------------------------

Lighting and Raking Out Filling the Pots Pots and Breakages Furnace Performance Blowing - Left Side Blowing - Right Side

|

Furnace Performance

Although this section concentrates on the Fourth Firing, some of the observations and photos are from earlier firings.

Fuel Use

The reason for changing to Sycamore and for de-barking the Horse Chestnut used during the glassmelting and blowing phases was to try to minimise the attack to the surface of the glass (see below: 'Glass attack'). In terms of wood used to fire the furnace, we used 1770 kilos (1.77 tonnes) over 13 days, at an average rate of 13 kilos per hour, or 136 kilos for each average 10.5 hour firing day. BurnbackDefining 'burnback': When flames come out of the front of the stoke hole tunnel. The cause appears to be that the pots are blocking the escape route for the flames and waste gases, forcing them to find an easier exit. This appears to be evident when looking at the photos of Firing Two and Firing Three, where there is a noticeable increase in burnback during Firing Three as empty pots had been placed in the furnace. With the extra air introduced by using a grate, burnback is marked, and leads to a less efficient use of the fire. The way to control it is to increase the gaps between the pots and between the side walls and the pots. When there is only one glassblower working, one of the large pots can be removed to increase the exit gap cross-sectional area.

Inclusions in the Glass

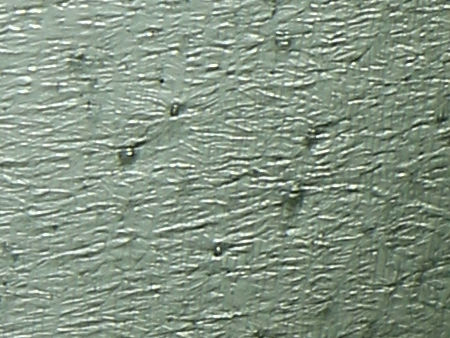

Glass Attack

We also noticed that the attack was much less - if any at all - on cobalt blue glass and opaque white and opaque yellow glass. Similarly, the blue-green glass used for the first few days did not suffer glass attack to any great degree, but as glass with manganese was added to the green glass, it began to show the characteristic clouding and eventual roughening of the surface. We experienced similar surface attack in the lehr from the 2005 firing, and Sarah Paynter attributed this to sulphur in the hot waste gases plus the lehr occasionally going over-temperature and slumping the glass vessels*. Significantly, this lehr was heated with the hot gases from one of the furnaces. We also experienced glass attack in 2006 when reheating glass which had an excess of sodium and potassium in it. It was very similar in appearance to the 2020 glass attack, and all three instances very likely have the same explanation. A post-graduate student at the University of Bournemouth kindly performed a hand-held XRF analysis of a sample of Horse Chestnut bark for us. The analysis showed that the bark contained 9000ppm (0.9%) of sulphur, which is very high (figures of 0% - 0.2% have been quoted as normal**). An industrial process, 'dealkalization', involves exposing the surfaces of soda-lime glass containers to sulphur dioxide or trioxide at 500°C–650°C by a now out-of-favour method of flooding the lehr with these gases. It removes sodium from the surface, which increases the resistance of the container to attack by its contents. We may be seeing an extreme, uncontrolled version of this process, and it does appear to be the most likely cause of the glass attack. (See Wikipedia: 'Dealkalization'.) At the end of Firing Three, we noticed a deposit of red-brown ash in the firing chamber. This may be the product of contaminated wood, and connected with glass attack. In an effort to minimise the glass attack we de-barked as much Horse Chestnut and Sycamore wood as possible. We also switched to Sycamore, and once to de-barked Horse Chestnut, when blowing glass. This, together with keeping the atmosphere in the melting chamber relatively calm, with just a small amount of flames exiting via the gathering holes, did allow us to produce vessels with much less, if hardly any, glass attack.

Insulating the Furnace

Destruction of Firebars

Improvements

Most of these improvements will be best accomplished by building them into the design for a replacement furnace planned for summer 2021. Alongside this will be altering the sizes of the large and small pots and increasing the size of the lehr. |

|

|

|

*Paynter, S. (2008) 'Experiments in the Reconstruction of Roman Wood-Fired Glassworking Furnaces: Waste Products and their Formation Processes' in JGS 50, pp.271-290. Click here for article. In particular, p.281: Dulling of the Glass.

**Oglesby, H.S. & Blosser, R.O. (1980) 'Information on the Sulfur Content of Bark and its Contribution to SO2 Emissions when Burned as a Fuel' in Journal of the Air Pollution Control Association 30:7, pp.769-772. Click here for article. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lehr Performance

There were no problems with the lehr during this firing. We lit it about 30 minutes before we started blowing, so it was at temperature (around 500°C) when needed. The only slumped vessel we had was due to it being placed over the edge of the shelf where it was directly in line with the waste gases which heated the lehr. As the lehr works on the updraft principle, the waste gases are directed by the shelves upwards along the wall, and that is the hottest place in the lehr. We burned mainly Chestnut and had no glass attack problems. There was a slight bloom on the glass when cold, but this washed off. The total amount used over 13 days was 455 kilos (0.455 tonnes), at an average rate of 5.17 kilos per hour, or 35 kilos for each average 6.8 hour firing day. With just one glassblower doing production work, we did fill the lehr rather easily on every blowing day. It is really too small for two glassblowers: we need about double the space, so we will widen it. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Home Gallery Contact Events & Projects Projects: 2019 Onwards Film & TV Archive & Links