Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

|

|

2020 Furnace and Lehr at Quarley - Firing Five - Furnace Performance and Lehr

Projects: 2019 Onwards

Shelter Build

Wood Gathering and Processing

General Preparation

Firepit Construction

Furnace Installation

Lehr Installation

Floodproofing

Firings One and Two

Firing Three

Firing Four

Firing Five

Firing Six

------------------------------------------------

Furnace Performance and Lehr Pots and Breakages Glassblowing

|

Furnace Performance

Fuel Use

To warm up the furnace to 1000°C in readiness for pot-filling, we used a mix of old fence posts and Chestnut. To maintain glassworking temperatures we used mainly Beech with a small amount of Walnut, all of which was heavily woodwormed. This resulted in a lower calorific value, burning more of this wood that one would normally expect, and is probably the main reason for the rate of fuel use (13.83kg/hr) being higher than that of Firing Four (13kg/hr). The reason for switching to Beech and Walnut after three to four hours of burning fence posts and Chestnut is that the fence posts had been treated with preservative and the Chestnut bark contains a high amount of sulphur: both of which could contaminate the hot gases and affect the glass whilst it was being worked. As we had less pots in the furnace (one large pot and two small pots), there was more room for the flames and products of combustion to flow through and escape. This resulted in far less burnback and a presumably more efficient burn. In an effort to stop the attack on the glass surface, we tried to keep the burn calm so there was very little flame around the melting and reheating areas. This did work to a degree, and the glass had less surface attack when doing this.

Furnace Atmosphere

Is this blue layer evidence of reduction? It is possible, as there were not uncommon instances of black sooty smoke, particularly when raising the furnace temperature in the morning. The formation of a glaze in a reducing atmosphere on the surface of an iron-rich fired clay would tend towards blue rather than green.

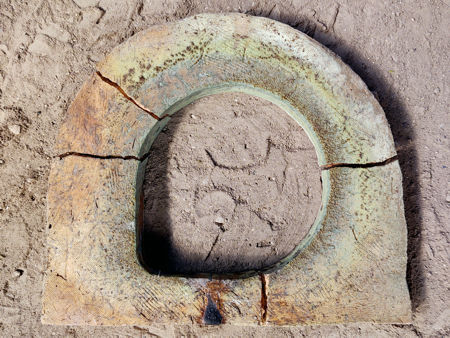

Furnace Condition

There are the normal blue-green to yellow deposits around the various holes in the furnace and on the inner surfaces of their associated collars and stoppers. Sarah Paynter, in her discussion of similar deposits from our 2005 and 2006 furnaces, says: "The composition of each of these samples was dominated by potassium, sulfur, calcium, and sodium", and: "These deposits have formed predominantly from compounds in the burning fuel that had volatilized in the furnace and then condensed on cooler surfaces. Some lime-rich fuel ash was also incorporated in the deposits." See Paynter 2008, p.287. Spillages from leaking pots on the floor of the firepit have combined with ash to form a hard, glassy deposit which is up to one inch thick, and the tiles have blackened and cracked. The fired daub supports for the stainless steel firebars have cracked and distorted, particularly at the entrance to the firepit, and the bars themselves have also badly oxidised. We have lost some of the collars and stoppers through breakage from thermal shock during use, but we treat these as throwaway. We also made some half-inch thick gaskets from ceramic fibre blanket to place behind the collars to stop heat leakage from the gaps between the furnace wall and the collars.

Glass Vessel Surfaces

The two goblets we made both showed glass attack. It was worst on each of the bowls, with some on the high points of the mereses, and virtually non-existant on the rest of the goblets. That on the bowl was the most interesting. There was very little attack whilst making the goblet on the blowing iron, but when puntied and reheated, the bowl developed serious attack (except for where the rim was reheated enough to be opened out). Presumably the sulphur is being absorbed into the glass as it becomes molten and the time spent reheating this area of the bowl is not enough for new attack to develop. Can it be stopped entirely? Raking out the ash each day may help. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

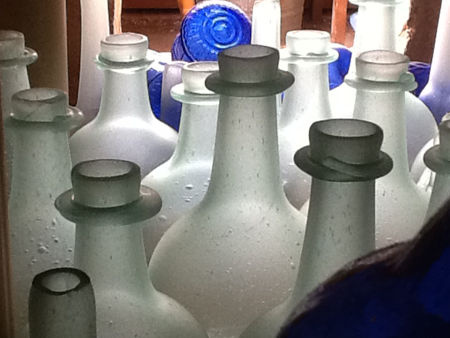

Lehr

We maintained a daily average temperature of 470°C, increasing it to around 500°C for the last half hour. The total amount of wood used over nine days was 283.5 kilos (0.2835 tonnes), at an average rate of 3.71 kilos per hour, or 31.5 kilos for each average 8.51 hour firing day. We used woodwormed Beech for the first two days, then added Pine offcuts and other salvaged wood to the Beech for the next seven days. The rate of fuel use (3.71kg/hr) was a marked improvement over that of Firing Four (5.17kg/hr) - probably due to maintaining slightly lower temperatures during the day. |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Home Gallery Contact Events & Projects Projects: 2019 Onwards Film & TV Archive & Links