Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

|

|

2022 Furnace ('Phoenix') and Lehr at Quarley - Etna Build and Firing

Projects: 2019 Onwards

Wood Gathering and Processing

Phoenix Firing Three

Repairs after Firing Three

Phoenix Firing Four

Phoenix Firing Five

The New Shelter Floor

The Electric Kiln

Rebuilding the Lehr

Etna Build and Firings

General Photos

Vesuvius Firepit Build

Vesuvius Superstructure Build

Vesuvius Firings

Repairs after Firing Five

Phoenix Firing Six

|

Etna Build and Firings

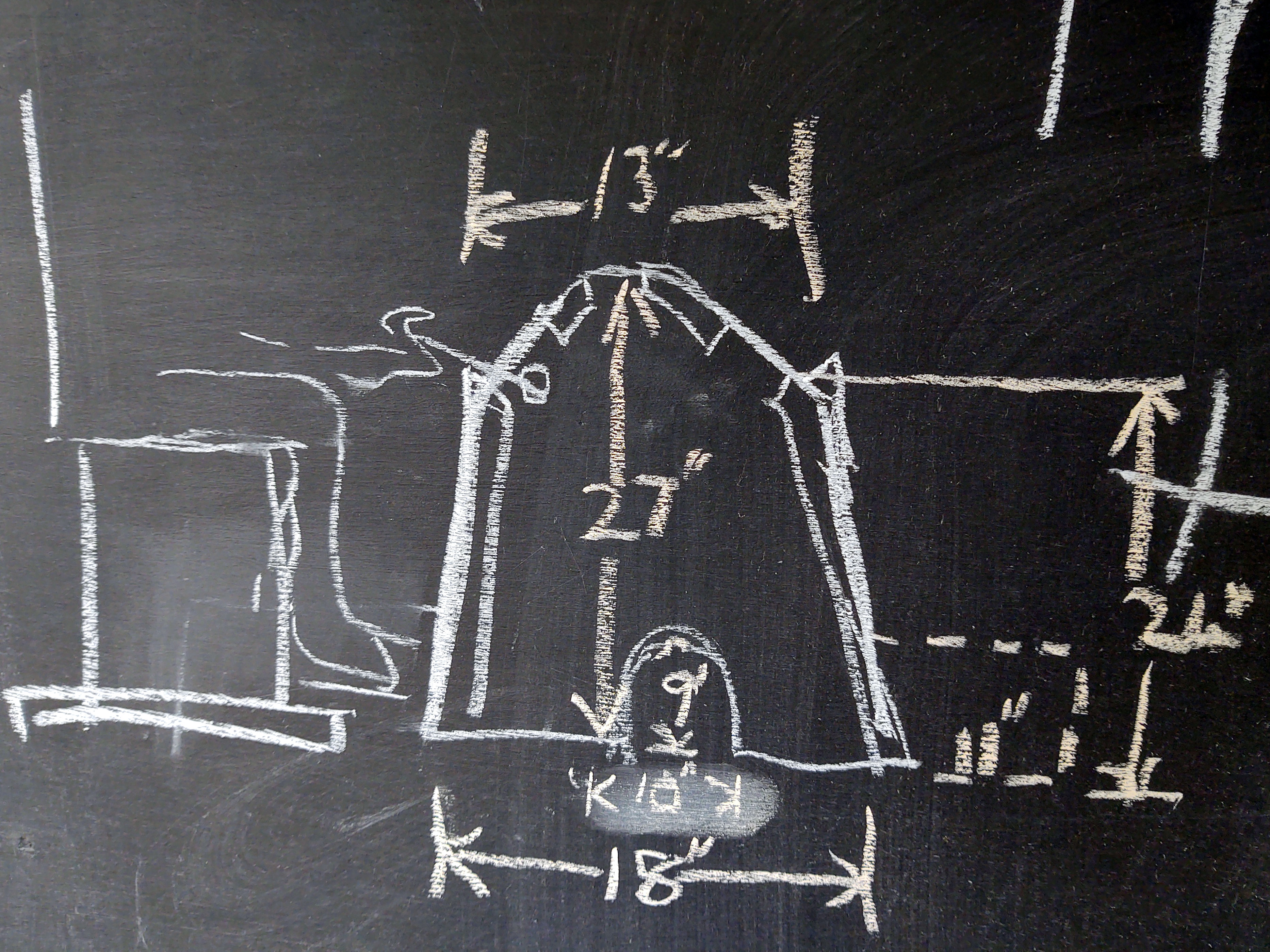

This was a small, quickly-built bead furnace to be used in place of the small furnace, Vesuvius, which we found to be unsuitable for beadmaking (see this page, and scroll down to 'Vesuvius Firing Two' and 'Vesuvius Firing Three'). It was built directly on the ground, outside the shelter, and covered by a plastic gazebo tent. It was built by David, over two days, as a monolithic structure, using daub. The walls were 1.5” to 2” thick, and it had a stoke hole tunnel, a domed roof, three working holes and a top hole. Each working hole had a shelf on which to rest a door. Many wood-fired bead furnaces that have been built have been of the ‘volcano’ type (similar to a rocket furnace), with no roof and having narrow, vertical slots in the wall to rest the bead mandrels. The disadvantage of this design is that it loses heat very quickly, and if the design is too small, not enough heat energy can be produced, and the furnace struggles to gain enough heat to melt glass quickly - particularly Roman-style glass, which is not as soft as modern bead-making glass. The advantage of this type of furnace is that one can work fairly close to it, using short mandrels. The advantage of our furnace is that the roofed chamber contains the heat in the top of the furnace and radiates it onto the bead, resulting in the ability to attain higher temperatures. The disadvantage of this furnace, particularly with the design we built, is that it radiates heat directly towards the beadmakers and forces them to work with longer mandrels. This will be addressed by redesigning the top to include a slot to the left of the working hole and increasing the height of the working hole itself. We will also shorten the stoke hole tunnel as the furnace was tricky to fire with the 21" lengths of wood we use. Another necessary addition is to build a simple roofed and walled shelter to protect the beadmaker(s). This furnace was very susceptible to the wind, and made working at it rather difficult in the windy weather we had during the firing. The shelter we plan to build will be easy to assemble and dismantle so it can be stored during the winter. The first firing of a few hours was to speed up the drying process. The next day, we fired it up to about 1050°C. We did not record these firings in detail. A final touch was to wrap the wall of the furnace with a one-inch-thick layer of ceramic fibre blanket, partly to help keep the heat away from the beadmaker, but also to provide some insulation. The effect of this on the furnace wall is seen in the fourth and third photos from last. It does appear to have induced a few cracks in the wall, but the furnace should be stable for future firings. Etna Firing One Over the course of a five-day firing, Etna burned about 40kg of Opepe per five-hour day (but this rate needs verification in future firings). We reached a top temperature of 1108°C, but Mike Poole (Tillerman Beads) found that around 970°C was a good temperature for working modern bead-making glass. Mike, who joined us in late August, for Phoenix Firing Six, initially found the furnace difficult to use, with short mandrels, the wind and the heat making beadworking tricky. We made longer mandrels and tried to shelter the furnace, with mixed results, but his experience was very useful in gaining information on improving the furnace design and the shelter. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Home Gallery Contact Events & Projects Projects: 2019 Onwards Film & TV Archive & Links