Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

|

|

2022 Furnace ('Phoenix') and Lehr at Quarley - The Electric Kiln

Projects: 2019 Onwards

Wood Gathering and Processing

Phoenix Firing Three

Repairs after Firing Three

Phoenix Firing Four

Phoenix Firing Five

The New Shelter Floor

The Electric Kiln

Rebuilding the Lehr

Etna Build and Firings

General Photos

Vesuvius Firepit Build

Vesuvius Superstructure Build

Vesuvius Firings

Repairs after Firing Five

Phoenix Firing Six

|

The Electric Kiln

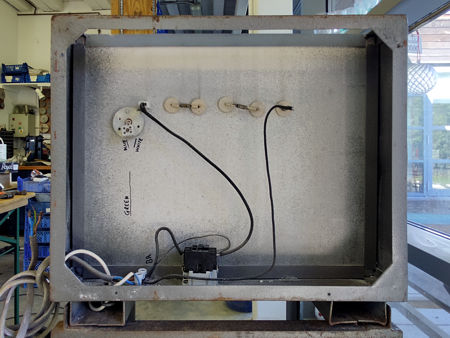

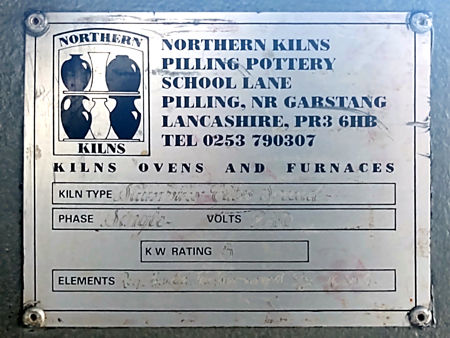

When we bought this kiln, it was in full working order, but in need of some TLC. It needed work on the high temperature insulation (HTI) brickwork in both the chamber and the door, relacement of the ceramic fibre sealing the door, a general clean, de-rusting and repainting, and the electrics needed to be checked. We addressed all of this, and using high temperature filler and fire cement, we repaired the HTI brickwork, including the broken lintel at the top of the chamber. To replace the ceramic fibre blanket on the door, we had to carefully thin down some 1" thick blanket to 0.25", then use high temperature filler to stick it in place. The wiring was checked and replaced where necessary by an electrician, and the point of exit for the wires was eventually swapped to the other side to make for a safer situation when it was installed in the shelter (on the newly-laid floor). The wall-mounted control box is very simple, allowing for adjustable ramp rates and soaks at given temperatures. The top temperature of the kiln is about 1000°C, but we will probably not need to go any higher than 800°C. This kiln is heavy! We had to move it from the workshop to the shelter in a van, remove the front wall of the shelter to be able to manhandle it into position using a trolley, and then to lift it onto its frame. It dates to at least pre-1995, as the phone number lacks a '1' in the area code (16th April 1995 - 'phONEday'). Previously, it had been used to garage and anneal lampworked glass objects. The chamber, at 9.25" tall by 15.5" wide by 15.5" deep, is able to comfortably hold two larger pots, two smaller pots and a couple of spare pots in case a replacement is needed. It will need a kiln batt floor to protect the soft HTI bricks, and we will eventually install a shelf or two underneath the kiln. An important, secondary use of the kiln is as an oven. We have since found (in Phoenix Firing Six) that after raising the temperature to about 750°C in the early morning, so the pots are hot-enough to transfer back into the furnace, the kiln will hold enough heat once turned off to cook lunch without using extra electricity. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Home Gallery Contact Events & Projects Projects: 2019 Onwards Film & TV Archive & Links