Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

|

|

2021 Furnace ('Phoenix') and Lehr at Quarley - IFoG Furnace Removal and Re-siting

Projects: 2019 Onwards

Woodshed Build

The Woodpile

IFoG Furnace Removal

Firepit Reconstruction

Furnace Superstructure Build

Phoenix Firing One

Repairs after Firing One

Phoenix Firing Two

Repairs after Firing Two

|

Removal and Re-siting

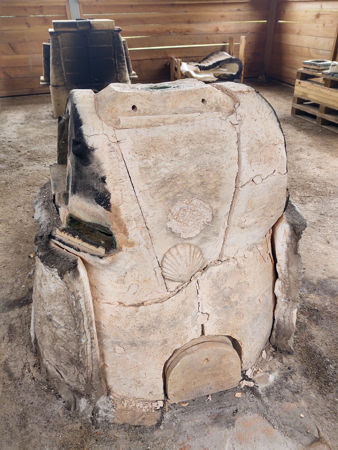

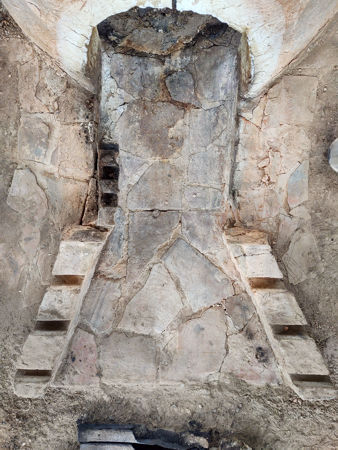

After removing the ceramic fibre, we could see the condition of the furnace. The 2020 and 2021 firings had taken their toll. There were more cracks, particularly visible in the roof section, which did not have its insulating layer of ceramic fibre on the hot face. The wall above the stoke hole had moved away from the gathering hole, only being supported by the tie rod. The pot support bars were glazed and very slightly bent. They were to be reused as the grate in the stokehole for the new furnace. The outer layer of ceramic fibre had created a partially-fired structure. Due to the low firing temperature (around 600°C - 700°C), the surface of the daub wall had turned a reddish orange colour, the chopped hay had burnt out, and the wall had become brittle. The ceramic fibre we had used to fill the cracks in the hot face had mainly survived intact. The furnace came apart very easily, although it broke into smaller pieces around the gathering holes and the holes for the pot support bars. Comparing the cross-sections of the wall with those of the 2019 disassembly (see this page), the extra cracks showed that the subsequent firings had caused the furnace to undergo further shrinkage. The firepit had been subjected to a lot of heat, and this showed in the blackening and cracking of the tiles and the fusing of a glass/ash mix to their surface. It clearly needed to be replaced, and that is recorded in the section on Firepit Reconstruction. The stainless steel grate had suffered serious attack: the first and second bars had totally disintegrated, and before Firing Six the second one had to be replaced with one of the others; bars three and four were also badly worn; and the daub bar supports were broken away at the hot end. Re-erecting it was a matter of laying some paving slabs and carefully placing the pieces of superstructure on them. Some areas of the wall had crumbled, notably the areas around the support bar fixings, and could not be included. We covered it with a large plastic bag to preserve it for as long as possible. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Home Gallery Contact Events & Projects Projects: 2019 Onwards Film & TV Archive & Links