Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

|

|

2022 Furnace ('Phoenix') and Lehr at Quarley - 'Phoenix' Firing Four - Blown Window Panes

Projects: 2019 Onwards

Wood Gathering and Processing

Phoenix Firing Three

Repairs after Firing Three

Phoenix Firing Four

Phoenix Firing Five

The New Shelter Floor

The Electric Kiln

Rebuilding the Lehr

Etna Build and Firings

General Photos

Vesuvius Firepit Build

Vesuvius Superstructure Build

Vesuvius Firings

Repairs after Firing Five

Phoenix Firing Six

------------------------------------------------

Furnace Performance and Lehr Non-blown Window Panes Blown Window Panes

|

Cylinder Glass

(Double Glossy)

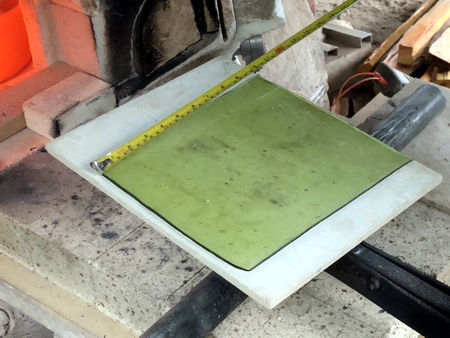

To make a cylinder glass window pane, a cylinder is blown, split lengthways either before or after annealing, re-heated to the softening point, the split teased apart and the cylinder opened and flattened. There are variations in the details of manufacture, but we adopted the technique of making a long bubble, flattening the base, puntying it and stretching and opening the cracked-off end, then annealing and cooling the resulting cylinder. The next day, cracking-off the base, splitting the cylinder using a trail of hot glass, then re-heating and flattening the cylinder to form a pane. Normally, a dedicated kiln is used for opening out the cylinder into a pane, but we only had the furnace! We cracked the base of each cylinder by playing a horizontal flame against the rotating vertical cylinder at the point of a small scored line. To split the first cylinder we scored a line along it with a diamond cutter, then laid a trail of hot glass along the score. Within a few seconds, the localised heat cracked the cylinder along the area touched by the hot glass. We found that the scored line was unnecessary, and the later ones were just marked with a marker pen to guide the placing of the hot trail. The size of our cylinder glass window panes was dictated by the width of the re-heating hole as well as the diagonal measurement of the lehr doorway. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Crown Glass

The method of making a crown glass window pane is well-known: a large bubble with a thick base is puntied, opened out - either with or without a folded rim - into a wide bowl form, thoroughly re-heated and spun to form a flat plate. One of the photos shows a crown without a folded rim being worked on. The size of our crowns was dictated by the diagonal measurement of the lehr doorway. Otherwise it would have been possible to make larger crowns. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Home Gallery Contact Events & Projects Projects: 2019 Onwards Film & TV Archive & Links