Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

|

|

2022 Furnace ('Phoenix') and Lehr at Quarley - 'Phoenix' Firing Six - Furnace Performance & Lehr

Projects: 2019 Onwards

Wood Gathering and Processing

Phoenix Firing Three

Repairs after Firing Three

Phoenix Firing Four

Phoenix Firing Five

The New Shelter Floor

The Electric Kiln

Rebuilding the Lehr

Etna Build and Firings

General Photos

Vesuvius Firepit Build

Vesuvius Superstructure Build

Vesuvius Firings

Repairs after Firing Five

Phoenix Firing Six

------------------------------------------------

Furnace Performance and Lehr Pots and Electric Kiln Glassblowing

|

Furnace Performance

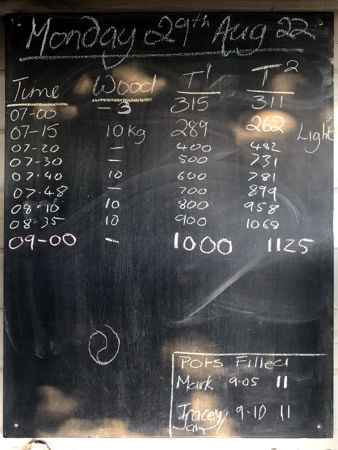

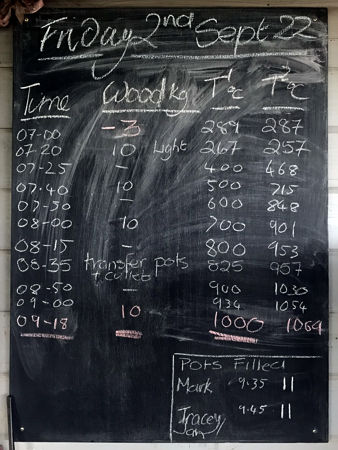

Fuel Use

On the next six mornings, by the time the furnace was ready to light, the average temperature in the firing chamber was around 243°C, and the furnace took on average 1.75 hours to reach 1000°C, using about 40kg of wood, at an average rate of 22.86 kilos per hour. Although the temperatures had dropped in the 15 minutes taken to prepare the furnace for firing (raking out the ashes and setting the fire), essentially due to an intake of cold air, the walls and floor would have had minimal loss in their core temperature. To fire the furnace to an average working temperature of 1050°C, we used 1172.50 kilos (1.1725 tonnes) of wood over seven days, at an average rate of 14.05 kilos per hour, or 167.50 kilos for each average 11.93 hour firing day. Discounting the fuel used and the time taken to warm up the furnace to 1000°C, the average rate of fuel use drops to 12.54 kilos per hour over an average 10 hour firing day. These are probably better figures to use as they more closely represent a steady state for the furnace which could be maintained for much longer periods, including overnight firing, and would result in a better quality glass and an earlier start to the glassblowing day. The overnight temperatures could be higher or lower than the normal working temperature of 1050°C, depending on what was needed: saving fuel or melting cullet. About one to one and a half small shovelfuls of ash were emptied from the firing chamber each morning.

Time and Temperature Gains

More significant was the time and temperature savings made through not having to replace the pots in the morning. The furnace could be lit sooner, which saved us about 50°C and allowed us to begin blowing about 30 minutes earlier (15 minutes less preparation time plus 15 minutes less for heating to 1000°C). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lehr Performance

Over the seven days, the lehr consumed an average of 4.58kg/hr of Oak, Opepe, Chestnut and Beech at an average temperature of 471°C, rising to 500°C for about 30 minutes at the end of each day before shutting it down. This represents an increase in fuel consumption for this larger lehr of about 1.23kg/hr compared with the smaller lehr from Phoenix Firing Five. As before, we kept the stoke hole closed down (damped down) to save fuel. Each morning, we removed less than a shovelful of ash and charcoal from the lehr firing chamber before re-lighting. |

|

|

|

|

|

|

| |

|

| |

|

| |

|

| |

|

|

|

|

| |

|

| |

|

| |

|

|

Home Gallery Contact Events & Projects Projects: 2019 Onwards Film & TV Archive & Links