Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

Home

Gallery

Contact

Events & Projects

Projects: 2019 On

Film & TV

Archive & Links

|

|

2022 Furnace ('Phoenix') and Lehr at Quarley - 'Phoenix' Firing Six - Pots and Electric Kiln

Projects: 2019 Onwards

Wood Gathering and Processing

Phoenix Firing Three

Repairs after Firing Three

Phoenix Firing Four

Phoenix Firing Five

The New Shelter Floor

The Electric Kiln

Rebuilding the Lehr

Etna Build and Firings

General Photos

Vesuvius Firepit Build

Vesuvius Superstructure Build

Vesuvius Firings

Repairs after Firing Five

Phoenix Firing Six

------------------------------------------------

Furnace Performance and Lehr Pots and Electric Kiln Glassblowing

|

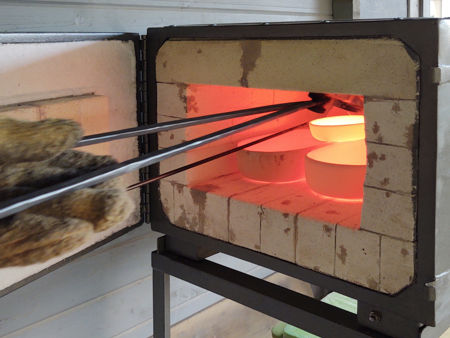

Pots and Electric Kiln

The régime we adopted was to preheat the kiln to 575°C, transfer the pots from the furnace and store them in the kiln overnight at 575°C, raise the kiln temperature to 750°C in the morning, and transfer the pots back into the furnace when it had reached 800°C. There was also room to store a spare pot at the back of the kiln. We had no pot breakages during the five-day firing, and the time and work saved in the morning was significant, allowing us to start blowing 30 minutes earlier than on previous firings. In addition, the stored heat in the kiln enabled us to cook meals for lunch and tea, thereby saving electricity. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Home Gallery Contact Events & Projects Projects: 2019 Onwards Film & TV Archive & Links